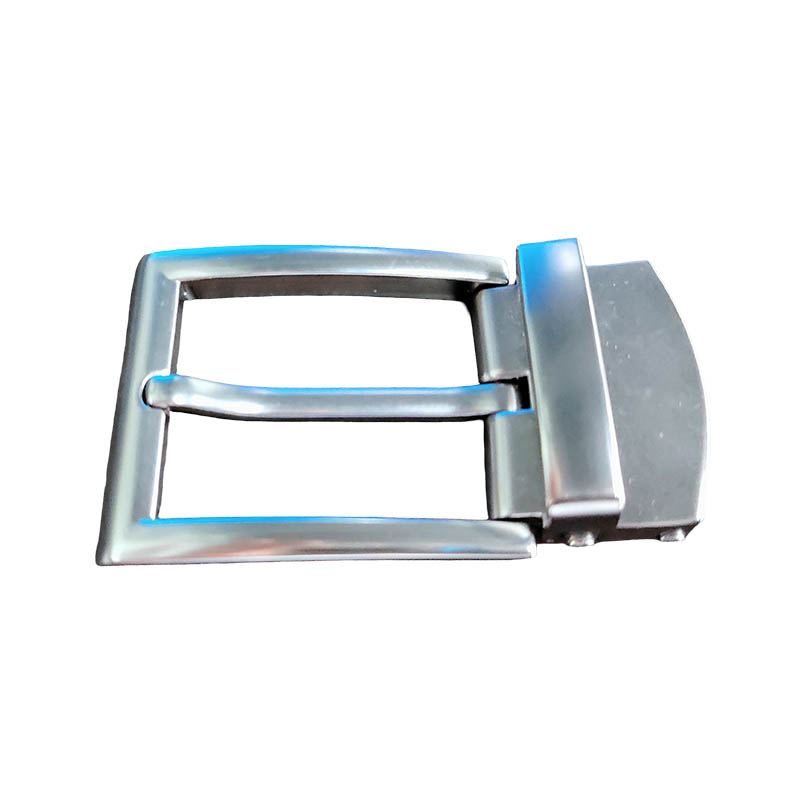

In men's accessories, belts are not only functional items but also a reflection of personal taste and aesthetic attention to detail. As the core component of a belt, the texture and feel of belt buckles directly affect the daily wearing experience.

- +86-13600257757

- jinjinze2025@qq.com

- No. 8, Lane 6, South Taisha Road, Nanzha, Humen, Dongguan City, Guangdong Province